The Future of U.S. Critical and Base Minerals

28 Jul 2022

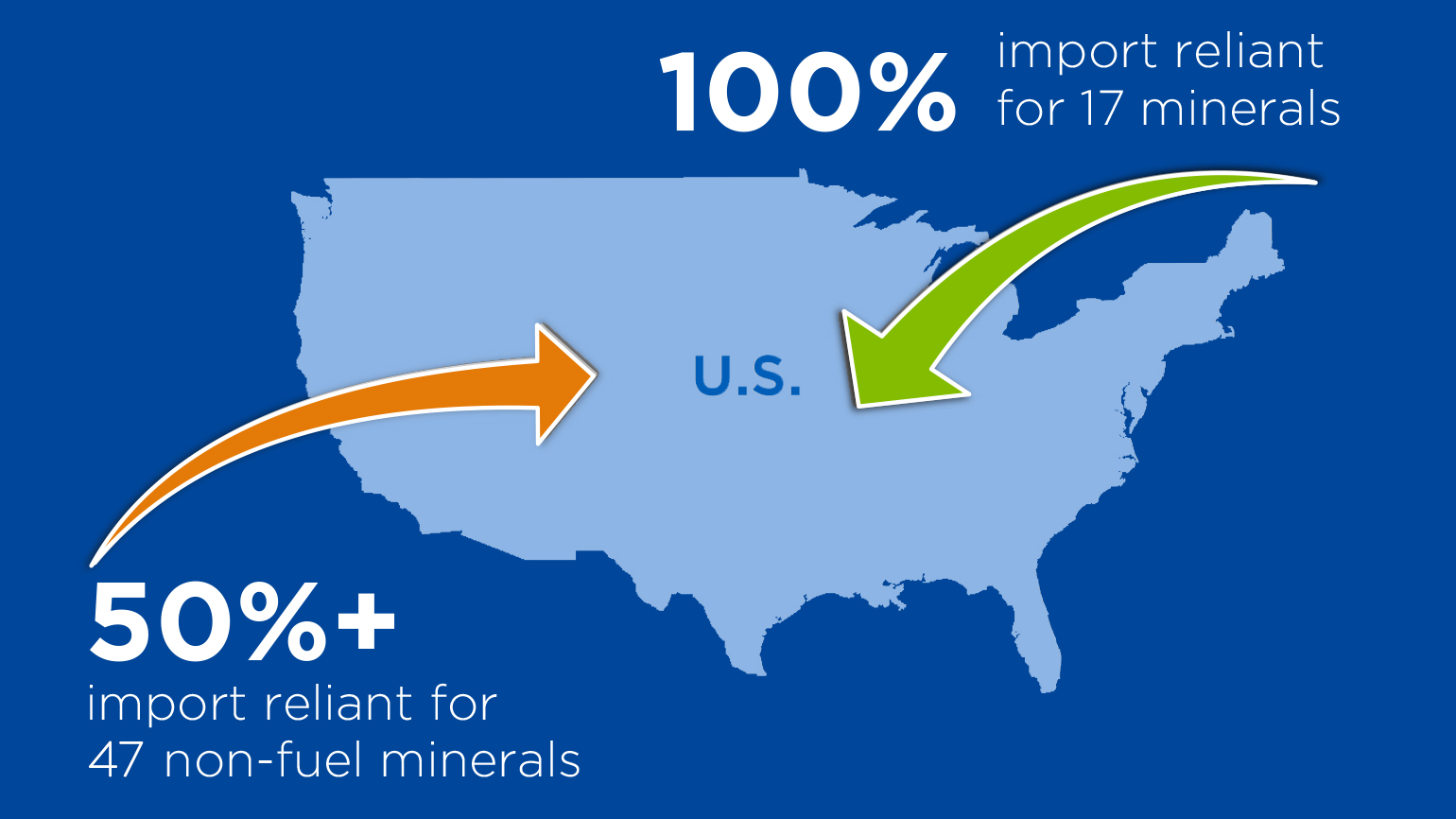

The U.S. is 50% or more reliant on imports for 47 different minerals, even though we have abundant natural resources domestically.

Critical and base minerals, like the lead, copper and zinc mined by Doe Run, are essential to technology innovations and countless products we use every day. Our ability to rebuild the nation’s infrastructure and move to a cleaner energy future requires mineral access. But the U.S. is at risk of being overly reliant on other countries to supply our needs.

Our domestic supply chain for minerals is suffering. The U.S. was the world’s top producer of minerals in 1990. Today, the U.S. is 50% or more reliant on imports for 47 different minerals, with China as the major source for 23 of them.

“The U.S. has tremendous natural resources and the ability to extract them using some of the world’s best technologies,” said Jose Hansen, vice president – sales and marketing at Doe Run. “But inconsistent energy policies and a lack of information sharing across the government often results in a regulatory landscape that hinders rather than helps new technologies. In the last several decades, the U.S. has lost the ability to process many of its materials and turn them into value-added metals. Lead, zinc and nickel are three examples of lost domestic metal production. This negatively impacts the entire supply chain for manufacturers utilizing those metals.”

Removing Barriers to Domestic Mineral Access

The use of lead and other minerals in applications and products to address climate change is just one example of the significant ways minerals will address the needs of the future. The U.S., however, will continue to be dependent on other countries to meet these needs until we remove some of the barriers to accessing our own minerals and converting those to metal.

Part of this starts with increasing investment in mineral exploration. Our land is rich with an estimated $6.2 trillion worth of minerals, but the U.S. only accounts for 11% of worldwide spending on mineral exploration – a missed opportunity to utilize the natural resources right under our feet.

One of the reasons this investment is low is because of the arduous process to permit a new mine. While permitting takes approximately two years in major mining countries, like Canada or Australia, it takes up to 10 years in the U.S. This prolonged process often results in the mine losing about one-third to one-half of its value before production even begins. Other regulatory challenges also hinder mineral processing companies from pursuing innovations.

“Our research and technology center has developed hydromet lead metal processing technologies that can be applied to battery recycling as well as to concentrates.” said Jose. “These hydromet technologies significantly reduce air emissions, and also can produce antimony and tin from recycled batteries as well as recover cobalt and nickel from complex concentrates here in Missouri. Developing these technologies requires better cooperation among the industry and regulators to reduce the unpredictability and uncertainty that hinders investment in these innovations.”

For companies like ours to be able to take advantage of these technologies and help the U.S. reclaim its position as a global leader in mineral extraction and processing, we need increased attention in four key areas:

- Permitting: Establish a clear, consistent and transparent path to the permitting of new mines and processing facilities.

- Processing: Revitalize U.S. mineral processing and recycling.

- Permission: Redefine the industry’s relationship with regulators and the public to work in greater collaboration toward sustainable mineral and metal production.

- People: Investment in mining and metallurgy programs to train the next generation of the mining workforce.

With properly educated people and the government providing a clear, transparent and timely permitting process for mines and processing facilities, the U.S. can better reap the full value chain of our natural resources and once again become the pre-eminent mineral and metal producer in the world. Only then can we provide the critical materials necessary to meet the challenges of tomorrow.