Missouri’s $2.5B Lead Battery Industry

17 Aug 2020

Missouri is home to one of the most productive lead mining districts in the world. So, it comes as no surprise that Missouri is second in the nation for the economic contribution of the lead battery industry.

In fact, the lead battery industry provides Missouri with a $2.5 billion annual economic impact. Nearly half of that, $1.2 billion, is contributed by The Doe Run Company. This is just one of many findings from the study, “Economic Contributions of the Missouri Lead Battery Industry,” prepared by EDR Group.

Lead batteries account for more than 70% of the global battery market. The market for all batteries is projected to grow from about $104 billion to $220 billion by 2030. Lead batteries play a critical role in a greener, more environmentally sustainable economy by supporting greater electrification of vehicles, storing renewable energy and being the most recycled consumer product in the world. Globally, lead batteries power over 1 billion cars, including electric and hybrid models, and 70% of global rechargeable energy storage needs are met by this technology.[1]

In Missouri, the lead battery industry provides:

- $2.5 billion annual economic impact

- $257 million annually in payroll

- 3,200 direct jobs

- 2,350 supplier/indirect jobs

- 2,590 jobs supported through workforce spending

- $527.3 million in labor income

As the largest economic contributor to the Missouri lead battery industry, Doe Run provides:

- $1.2 billion total economic impact

- $112.3 million annually in payroll

- 1,160 direct jobs

- 1,110 supplier/indirect jobs

- 1,210 jobs supported through workforce spending

- $240.4 million in labor income

“We have a strong history of providing jobs in Missouri,” said Jerry Pyatt, Doe Run president and CEO. “We continue to invest in innovation for our operations, so we can sustain our business for the long term – providing quality products to our customers and enduring benefits for our employees and neighboring communities.”

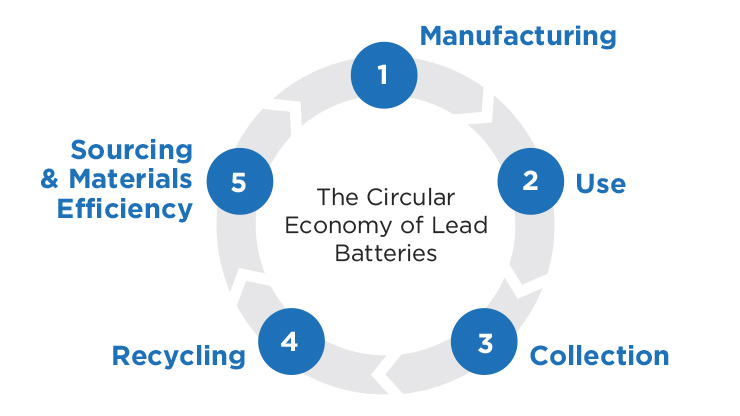

Leading the Way with a Circular Economy

In addition to Doe Run, other major employers, like EnerSys and Clarios, have operations in Missouri. These combined operations represent mining, manufacturing, use, collection, recycling and material sourcing – each a critical step of a successful circular economy model. In the U.S., only 16% of all businesses have moved to a circular economy. With its 99% recycling rate and cradle-to-cradle manufacturing process, the lead battery industry is leading the way. Each year, 129 million lead batteries are recycled in the U.S. The lead metal and plastic recovered through the recycling process are re-used to manufacture new batteries. In fact, about 80% of a new lead battery is comprised of recycled material.

Missouri’s lead batteries are contributing to global industries. Lead batteries support transportation, wireless communication and data storage. They are also critical in providing energy storage solutions for growing renewable energy and grid storage applications. By 2035, nearly half of global total electricity capacity is projected to come from renewable energy sources, like solar and wind. Read more about the future of energy storage here.

The Missouri study was a subset of the Economic Contribution of the U.S. Lead Battery Industry, prepared by the Economic Development Research Group at the request of Essential Energy Everyday and Battery Council International (BCI). Read more about the full study and methodology here.

[1] “Renewable Energy Storage,” July 9, 2018, Essential Energy Everyday